A metal workbench is commonly found in the business and industrial sectors as a versatile space to work on projects. Metal workbenches are usually built using stainless steel since it’s strong and resistant to corrosion. The stainless steel creates a strong frame and provides the workbench with a finished look. If the workbench is used where hygiene is important, stainless steel is easy to clean. A metal workbench may be applied in many facets, and many designs exist. Read More…

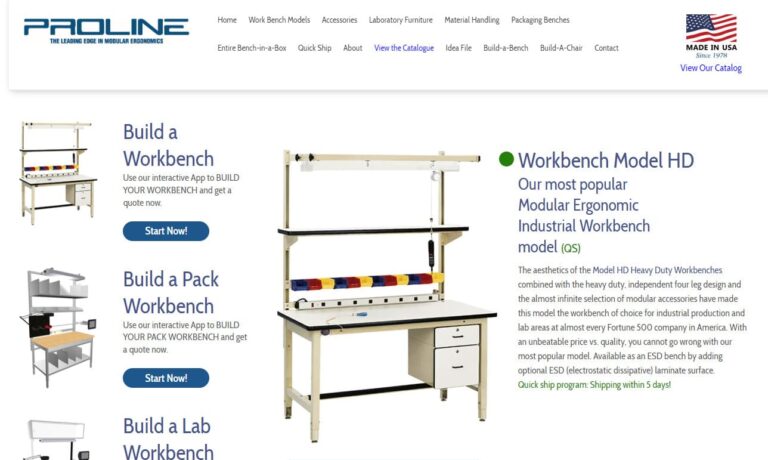

Our workbenches come in a variety of styles including ergonomic height adjustable, chemical resistant, ball transfer surface, computer stations, laminar flow stations and more.

As a workstation manufacturer, Pro-Line offers industrial furnishing that increases employee productivity through creating an improved employee work environment.

At Industrial Profile Systems, we take pride in designing and manufacturing high-quality workstations that elevate efficiency, organization, and safety in industrial and commercial environments. We specialize in creating durable, modular, and ergonomically optimized workstations tailored to the unique needs of our customers, whether they require single-user setups, multi-station configurations,...

At Teclab Kalamazoo Technical Furniture, we take pride in designing and manufacturing high-quality technical workstations and furniture solutions that meet the needs of demanding professional environments. We specialize in creating durable, ergonomic, and highly functional workstations that support laboratories, research facilities, manufacturing operations, and technical workspaces of all sizes.

At Hergo Ergonomic Workspace Solutions, we dedicate ourselves to creating work environments that enhance comfort, efficiency, and productivity. We design and manufacture high-quality ergonomic workstations, tailored to meet the diverse needs of modern offices, industrial facilities, and technology-driven spaces.

More Metal Workbench Manufacturers

Metal workbenches are essential fixtures in industrial, commercial, and residential settings, providing sturdy and reliable surfaces for a wide range of tasks. The production of metal workbenches typically begins with expert metal fabrication, where high-quality steel or aluminum sheets are cut to dimension and formed into the various components that make up a robust work table. Once these pieces are molded and shaped precisely, they are welded together—often with the aid of automated welding machines known for their consistency and efficiency. This advanced manufacturing process ensures that every steel workbench or aluminum workbench delivers the structural integrity and longevity required for demanding environments.

Metal workbenches offer numerous advantages over wooden or composite alternatives. They are highly sanitary, effortless to clean, require minimal maintenance, and are resistant to damage from common greases, oils, chemicals, and solvents. Whether you are outfitting a home garage, a professional automotive repair shop, an engineering workshop, or a laboratory, investing in a quality metal workbench means choosing durability, versatility, and long-term value.

Considerations When Choosing a Metal Workbench

When selecting the ideal metal workbench for your application, several key factors should guide your decision. Understanding these considerations can help you choose a workbench that meets your functional needs while providing optimal value and performance.

Duty Ratings: Medium, Heavy, or Super Heavy Duty

The load capacity and intended application of your workbench will determine whether a medium, heavy, or super heavy-duty workbench is required. The primary differences between these classifications lie in the steel thickness and overall construction. For instance, a super heavy-duty workbench may feature a 0.08 in (2 mm) galvanized steel coat and a 1.7 in (44 mm) thick hardwood or composite core, supporting extremely heavy equipment and tools. In contrast, a medium-duty workbench might utilize a 0.008 in galvanized steel top without a core—suitable for lighter assembly tasks, electronics work, or general use.

Standard and Custom Workbench Sizes

Metal workbenches are available in a vast array of standard sizes to suit diverse requirements in workshops, factories, laboratories, and garages. The most common dimensions (WxDxH) include:

- 1200 x 750 x 840 mm

- 1500 x 600 x 840 mm

- 1500 x 900 x 840 mm

- 2000 x 600 x 840 mm

- 2000 x 750 x 840 mm

- 2000 x 900 x 840 mm

However, many manufacturers offer custom sizes and extensions to fit unique spaces and specific operational needs. Before purchasing, carefully measure your available workspace and evaluate the typical tasks you will perform—this will guide you toward the optimal bench size and configuration.

Looking for a specific size or custom workbench solution? Contact leading metal workbench manufacturers to discuss your unique requirements and receive a tailored quote.

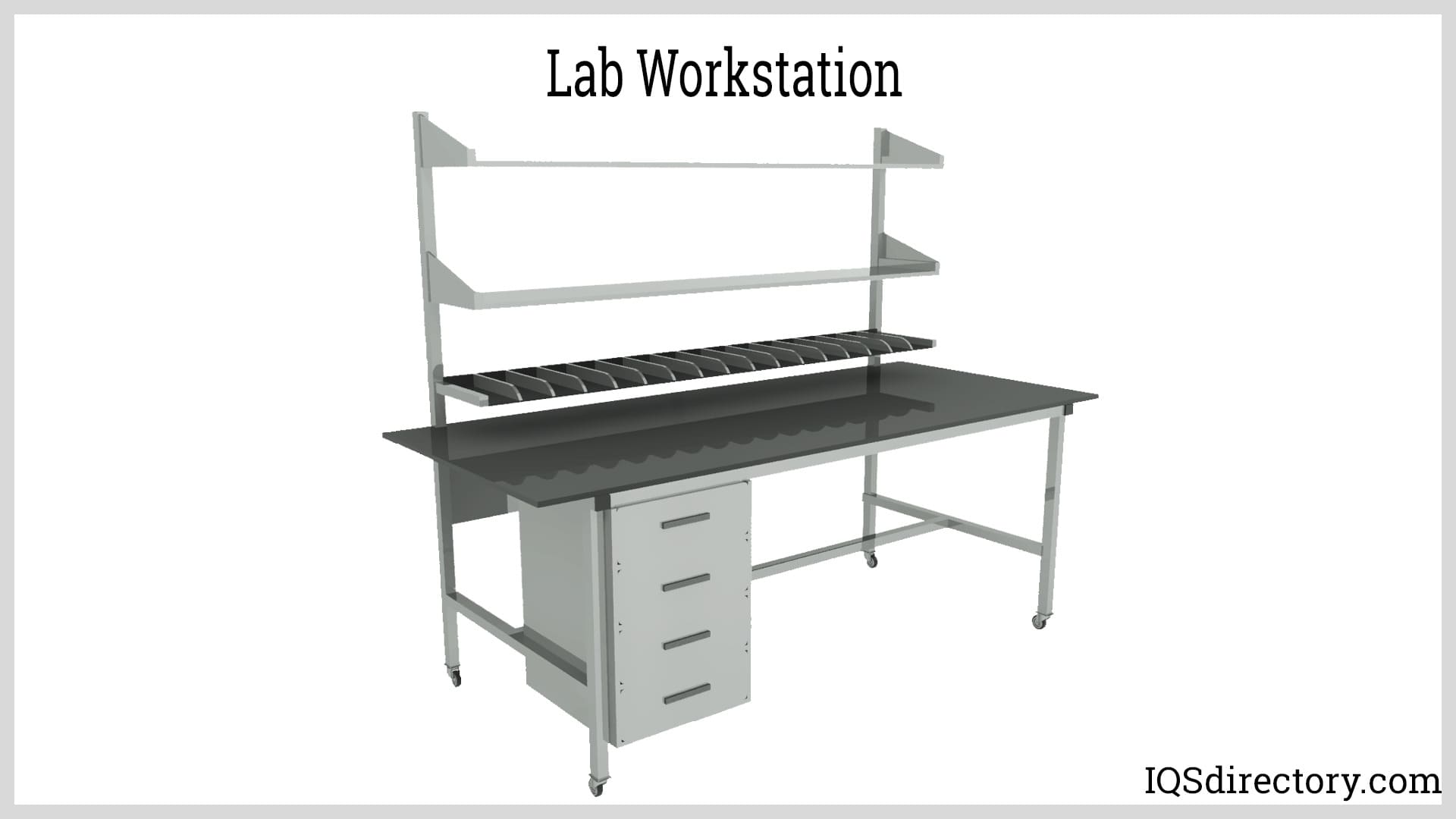

Workbench Accessories and Modular Expansion

One of the greatest advantages of modern metal workbenches is their modular design, allowing for a wide range of accessories and add-ons. This flexibility enables customization for virtually any workflow, from industrial manufacturing to electronics assembly and laboratory research. Common accessories include:

- Lockable cupboards and storage cabinets

- Adjustable shelving systems

- Integrated drawers for tool organization

- Dedicated vices and clamps

- Lighting rails and overhead lights

- Power outlets and USB charging ports

- Pegboards and tool racks

- Anti-static mats and grounding kits for sensitive electronics

How can you optimize your productivity with modular workbenches? Explore accessory options that align with your workflow for increased efficiency and organization.

Type of Steel and Material Selection

Workbenches are most commonly constructed from heavy-duty mild steel angle iron, renowned for its strength, impact resistance, and adaptability. Mild steel—also referred to as plain steel or carbon steel—is an industry standard for both industrial and domestic workbenches due to its cost-effectiveness and robustness. Galvanized steel is particularly prized for its corrosion resistance, making it suitable for environments exposed to moisture or chemicals. In specialized settings, stainless steel workbenches or aluminum workbenches may be chosen for their unique properties, such as enhanced hygiene (critical in food processing or pharmaceutical labs) or lighter weight for easy relocation.

Surface Options and Finishing

The choice of workbench surface material directly impacts usability and longevity. Stainless steel surfaces are favored for their easy cleaning, resistance to rust, and attractive appearance. However, in high-friction or metal-to-metal applications, stainless steel may not be ideal as it can sometimes promote galling or seizing of fasteners. For heavy-duty industrial use, powder-coated steel or hardwood inlays may offer additional resilience against scratches, dents, and chemical spills. Consider the types of tasks you will perform—whether you need a heat-resistant, anti-static, or chemical-resistant work surface, there is a metal workbench solution available.

Durability, Weight Capacity, and Load Ratings

Assess the expected impact forces, static loads, and daily wear your workbench will endure. For occasional or light-duty use, an 18 gauge economy workbench may suffice, offering portability and cost savings. For more demanding applications, such as metal fabrication, heavy assembly, or automotive repair, 16 gauge standard duty or 14 gauge heavy-duty workbench tops are recommended. These thicker steel tops not only resist corrosion and abrasion but also withstand significant impacts without warping or denting. Always verify the stated weight capacity and ensure it aligns with your intended use.

Not sure how much weight your workbench needs to hold? Refer to your equipment specifications or consult with a metal workbench specialist to ensure safety and durability.

Mobility and Portability

In dynamic workspaces, mobile metal workbenches equipped with heavy-duty casters and handles provide the flexibility to quickly reconfigure your layout or move workstations between departments. Stainless steel carts or rolling workbenches are especially valuable in settings where cleaning, transport, or space optimization is a priority. Look for locking casters to ensure stability when stationary. If you require both mobility and high load capacity, consult manufacturers for reinforced mobile workbench models.

Ergonomics and Adjustable Height Features

Ergonomics is a critical consideration for workplace safety and productivity. Adjustable height workbenches support a range of users, accommodating both sitting and standing positions to reduce the risk of musculoskeletal disorders. Modern designs may include manual, pneumatic, or electric height adjustment mechanisms, making it easy to tailor the workbench to each user’s preferences. For shared workspaces or applications requiring frequent reconfiguration, investing in an ergonomic adjustable workbench can lead to healthier employees and greater efficiency.

Curious about ergonomic workbenches for your team? Discover the latest height-adjustable and sit-stand metal workbench options that support workplace wellness initiatives.

Types of Metal Workbenches

Understanding the different types of metal workbenches will help you identify the best solution for your specific operations. Here is an overview of popular workbench types and their primary applications:

Standard Workbenches

Standard metal workbenches are versatile platforms, ideal for general maintenance, assembly, and repair tasks in a variety of environments. Their modular construction allows for easy customization and expansion with accessories, making them a staple in both industrial and laboratory settings. These workbenches are commonly used in machine shops, electronics assembly lines, and educational labs.

Production Workbenches

Production workbenches are engineered to streamline workflow, boost productivity, and support repetitive tasks in manufacturing, packaging, or research environments. Features may include conveyor rollers, integrated power supplies, or specialized fixturing for assembly lines and quality control stations. Their robust build and ergonomic layouts make them indispensable for high-volume operations.

Cantilever Workbenches

Cantilever workbenches feature a unique design with a formed steel front beam and rear panel, maximizing legroom and facilitating easy cleaning beneath the bench. This structure also allows for unobstructed storage of carts or equipment below. Cantilever benches are often selected for heavy-duty applications, electronics assembly, and laboratory work that demands easy access and flexibility.

Material Handling Workbenches

Material handling workbenches are purpose-built for shipping, receiving, and packaging operations. With options for integrated scales, conveyor belts, and sorting systems, these benches help streamline logistics and improve organization. They are ideal for warehouses, fulfillment centers, and mailrooms where efficient material flow is essential.

Specialty Workbenches

Depending on your industry or unique operational demands, you may require specialized metal workbenches such as:

- ESD workbenches (Electrostatic Discharge) for electronics manufacturing

- Cleanroom workbenches for pharmaceutical or semiconductor applications

- Welding workbenches with fire-resistant surfaces and grounding lugs

- Mobile tool benches with integrated tool storage and power distribution

Which type of workbench is best for your application? Compare metal workbench types and find the optimal solution for your workflow.

Advantages of Metal Workbenches

Steel workbenches and other metal-based designs offer substantial advantages, making them the preferred choice across industries. Key benefits include:

- Exceptional durability: Metal workbenches withstand heavy loads, impacts, and continuous use—ideal for industrial settings.

- Longevity: Properly maintained metal workbenches remain serviceable for decades, delivering outstanding return on investment.

- Environmental sustainability: Steel and aluminum are recyclable materials, making modern metal workbenches an eco-friendly option.

- Low maintenance: Resistant to stains, moisture, and chemicals, these benches are easy to clean and require minimal upkeep.

- Hygienic surfaces: Metal tops are non-porous, inhibiting the growth of bacteria—crucial in laboratories, food processing, and healthcare.

- Fire and heat resistance: Unlike wood, metal benches offer protection against sparks and high temperatures in welding or fabrication shops.

- Customization: Modular accessories, adjustable components, and a range of finishes allow for full customization to your specific needs.

Want to know how metal workbenches can improve your workflow? Explore more benefits and see real-world use cases.

Common Applications for Metal Workbenches

Metal workbenches are indispensable in a variety of sectors. Their applications include:

- Manufacturing and assembly: Support for heavy machinery, precision components, and assembly lines.

- Automotive workshops: Engine rebuilding, component cleaning, and tool organization.

- Laboratories: Chemical resistance and easy sanitization for scientific research and testing.

- Electronics assembly: ESD-safe surfaces and integrated grounding for sensitive circuitry.

- Woodworking and metal fabrication: Sturdy surfaces for cutting, welding, and finishing materials.

- Education and training centers: Durable, safe workstations for students and apprentices.

- Home garages and DIY: Versatile solutions for home improvement, repairs, and crafts.

- Food processing and pharmaceutical: Hygienic, corrosion-resistant surfaces for cleanroom and sanitary environments.

Searching for metal workbenches for a specific application? Browse workbench solutions by industry and use case.

Factors to Consider Before Buying a Metal Workbench

Before investing in a metal workbench, consider these decision factors to ensure the best fit for your needs:

- Budget: Balance initial costs with long-term durability and maintenance savings.

- Workspace layout: Assess available space, workflow, and required bench size/configuration.

- Load requirements: Confirm the weight capacity aligns with your heaviest tasks.

- Environmental conditions: Choose materials and finishes suited to humidity, temperature, and chemical exposure.

- Compliance: Ensure workbenches meet industry safety standards and ergonomic guidelines.

- Future scalability: Select modular systems that can grow with your operations.

- Warranty and service: Review manufacturer warranties and support services for peace of mind.

Need help choosing the right workbench? See our comprehensive buying guide for metal workbenches.

Choosing the Right Metal Workbench Manufacturer

Selecting the best metal workbench manufacturer is essential for ensuring quality, durability, and after-sales support. To achieve the most productive outcome, compare at least five manufacturers using our extensive directory of metal workbench companies. Each manufacturer’s business profile page highlights their areas of expertise, capabilities, certifications, and customer reviews.

Our platform allows you to:

- Review detailed company profiles and capabilities

- Preview manufacturer websites with our proprietary website previewer

- Contact manufacturers directly via integrated forms for more information or custom quotes

- Submit a single RFQ (Request for Quote) to multiple suppliers simultaneously

- Compare pricing, delivery times, and technical support

Ready to request quotes or compare suppliers? Start your search for trusted metal workbench manufacturers and make an informed purchasing decision.

Frequently Asked Questions About Metal Workbenches

What is the difference between a steel workbench and an aluminum workbench?

Steel workbenches prioritize strength, impact resistance, and durability, making them ideal for heavy-duty industrial applications. Aluminum workbenches, while lighter and more portable, are favored in environments where weight savings and corrosion resistance are important—for example, cleanrooms or electronics assembly areas.

Are stainless steel workbenches worth the investment?

Stainless steel workbenches are an excellent choice for laboratories, food processing, and medical environments due to their non-porous, sanitary surfaces and resistance to rust and corrosion. While the initial investment may be higher, the long-term benefits—such as easy cleaning and compliance with hygiene standards—can outweigh the costs.

How do I maintain and clean a metal workbench?

Regularly wipe the surface with a mild detergent and water to remove dirt, grease, and chemicals. Avoid abrasive pads that can scratch the finish, and inspect for signs of corrosion or damage. For stainless steel, use appropriate polish to maintain shine and resist fingerprints.

Can metal workbenches be customized?

Yes! Most reputable manufacturers offer a range of customization options, including size, surface material, accessories, color finishes, and even branding. Customization ensures your workbench fits perfectly into your workflow and workspace.

What is the typical lead time for a custom metal workbench?

Lead times vary depending on the complexity of the design, manufacturer workload, and your location. Standard models may ship within days, while fully customized solutions might require several weeks. Always check with your supplier for current production timelines.

Get Started: Request a Quote or Speak with an Expert

Whether you are upgrading an existing workspace or building a new facility, the right metal workbench will provide a foundation for efficiency, safety, and productivity. Use our directory to request quotes, compare manufacturers, and speak directly with metal workbench specialists about your needs. Our experts can guide you through the process, from material selection to installation and after-sales support.

Ready to transform your workspace with a custom metal workbench? Contact us today to begin your search and receive personalized recommendations.

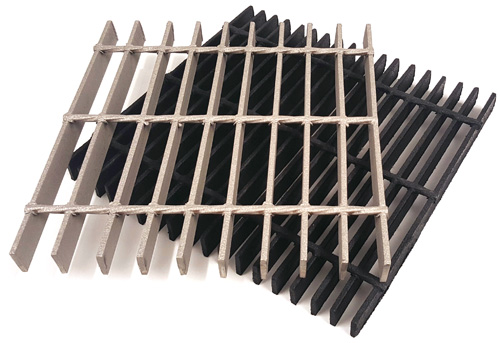

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services